Respect for the cold chain is crucial to ensure goods are delivered in optimal condition to customers. It requires expertise that only a specialist can provide. Carrier Transicold is dedicated to maintaining your cold chain and maximizing cost efficiency, while limiting environmental impact.

Developing innovative cold chain solutions is ingrained in the culture of Carrier Transicold, where respect for the cold chain is crucial to ensure perishable, fresh and frozen goods are delivered in optimum condition to customers.

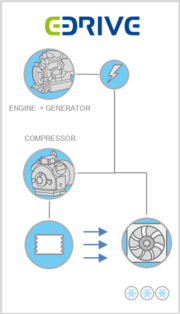

The E-DRIVE all-electric technology removes mechanical transmissions found in belt-driven technology by transforming engine power into electricity.

This unique and patented solution delivers superior cold chain performance while reducing CO2 footprint and total cost of ownership :

The ECO-DRIVE is a power module, which is fitted to the side of the truck’s chassis. 400 volt / 50 Hz is delivered and constantly available. This pump is connected to the truck engine via a PTO (power take off). The hydraulic system drives a generator located inside the power module delivering a constant 400 volt / 50 Hz.

A control is integrated within the hydraulic system, called X-Flow. This innovative system operates independent of the truck’s engine speed and ensures 100 % capacity is always available. The system communicates with the CAN bus of the truck.

Learn more

Clean the Equipment

Pre-Cool The Body

Check the Condition of Strip Curtains

Respect Correct Temperature

Respect Airflow

Separate Goods

Shut Down Unit when Opening Doors

The Right Setting for Transport Temperature

|

-20°C

|

Ice and ice cream

|

|

-18°C

|

Frozen or quick (deep)-frozen fish, fish products, molluscs and crustaceans and all other quick (deep)-frozen foodstuffs

|

|

-12°C

|

All frozen foodstuff (except butter)

|

|

-10°C

|

Butter

|

|

On melting ice or at temperature of melting ice

|

Untreated fish, molluscs and crustaceans (except for live fish, live molluscs and live crustaceans)

|

|

Either at +2°C or at temperature indicated on the label and/or on the transport document

|

Minced meat (and any preparations thereof)

|

|

+3°C

|

Red offal (and any preparations thereof)

|

|

+4°C

|

Game (other than large game), poultry (and any preparations thereof) and rabbits

|

|

Either at +6°C or at temperature indicated on the label and/or on the transport documents

|

Meat products (except for fully treated by salting, smoking, drying, or sterilization)

|

|

+6°C

|

Pasteurized milk, fresh dairy products (yoghurt, kefir, cream and fresh cheese*)

|

|

Ready cooked foodstuffs (meat, fish, vegetables)

|

|

|

Ready to eat prepared raw vegetables (which have been diced, sliced or otherwise size reducted, but excluding those which have only been washed, peeled or simply cut in half) and vegetables products

|

|

|

Fishs products (except for product fully trated by salting, smoking, drying, or sterilization) not listed above

|

|

|

Raw milk (when milk is collected from the farm for immediate processing, the temperature may rise during carriage to +10°C)

|

|

|

+7°C

|

Red meat (and any preparations thereof) and large game (other than red offal)

|

Keeping your cold chain cost effective is a major challenge. While on the road, it’s important to minimize energy consumption while maintaining performance.

Carrier Transicold offers a wide range of solutions to preserve freshness, ensure safety during transport and enhance the overall appearance and quality of food and beverage retail.

(Extract of A.T.P. Europe regulations March 1974)

Before putting a refrigerated vehicle into use, it must be approved by the regional health authorities.

The refrigerated unit is an insulated unit with a cooling system which makes it possible, at a mean outside temperature of +30°C, to lower the temperature inside the empty body and to maintain this low temperature as follows:

The cooling capacity of a unit is determined by a test carried out in one of the registered testing centers and certified by an official report.

Test results are valid for 6 years.

This reference must be followed by the appropriate identification marks from the following list:

| Standard Class A refrigerated unit | FNA |

| Reinforced Class A refrigerated unit | FRA |

| Reinforced Class B refrigerated unit | FRB |

| Reinforced Class C refrigerated unit | FRC |

In addition to the above identification marks, the date (month and year) of expiry of the approval certificate must be indicated.

| Example: | MODEL FRC |

| 6 – 2010 (6 = June, 2010 = year) |

DIN 8958